Gas turbines:

Introduction:

The development of the gas turbine engines as an aircraft power plant has been so rapid that it is difficult to appreciate that prior to the 1950's very few people had heard of this method of aircraft propulsion. The possibility of using a reaction jet had interested aircraft designers for a long time, but initially the low speed of early aircraft and the unsuitability of a piston engine for producing the large high velocity airflow necessary for the jet presented many obstacles.

The German engineer Hans von Ohain built the first running gas turbine engine.

Doing this, as described in Part 2, but in all instances the resultant reaction or thrust exerted on the engine is proportional to the mass or weight of air expelled by the engine and to the velocity change imparted to it. In other words, the same thrust can be provided either by giving a large mass of air a little extra velocity or a small mass of air a large extra velocity. In practice the former is preferred, since by lowering the jet velocity relative to the atmosphere a higher propulsive efficiency is obtained.

METHODS OF JET PROPULSION

The types of jet engine, whether ram jet, pulse jet, rocket, gas turbine, turbo/ram jet or turbo-rocket, differ only in the way in which the 'thrust provider', or engine, supplies and converts the energy into power for flight.

The ram jet engine is an athodyd, or aero-thermodynamic-duct to give it its full name. It has no major rotating parts and consists of a duct with a divergent entry and a convergent or convergent-divergent exit. When forward motion is imparted to it from an external source, air is forced into the air intake where it loses velocity or kinetic energy and increases its pressure energy as it passes through the diverging duct. The total energy is then increased by the combustion of fuel, and the expanding gases accelerate to atmosphere through the outlet duct. A ramjet is often the power plant for missiles and target vehicles, but is unsuitable as an aircraft power plant because it requires forward motion imparting to it before any thrust is produced.

The pulse jet engine uses the principle of intermittent combustion and unlike the ramjet it can be run at a static condition. The engine is formed by an aerodynamic duct similar to the ramjet but due to the higher pressures involved; it is of more robust construction. The duct inlet has a series of inlet 'valves' that are spring-Ioaded into the open position. Air drawn through the open valves passes into the combustion chamber and is heated by the burning of fuel injected into the chamber. The resulting expansion causes a rise in pressure, forcing the valves to close, and the expanding gases are then ejected rearwards. A depression created by the exhausting gases allows the valves to open and repeat the cycle. Pulse Jets have been designed for helicopter rotor propulsion and some dispense with inlet valves by careful design of the ducting to control the changing pressures of the resonating cycle. The pulsejet is unsuitable as an aircraft power plant because it has high fuel consumption and is unable to equal the performance of the modern gas turbine engine.

Although a rocket engine is a jet engine, it has one major difference in that it does not use atmospheric air as the propulsive fluid stream. Instead, it produces its own propelling fluid by the combustion of liquid or chemically decomposed fuel with oxygen, which it carries, thus enabling it to operate outside the earth's atmosphere. It is, therefore, only suitable for operation over short periods.

The application of the gas turbine to jet propulsion has avoided the inherent weakness of the rocket and the athodyd, for by the introduction of a turbine-driven compressor a means of producing thrust at low speeds is provided. The turbo-jet engine operates on the 'working cycle' as described in Part 2. It draws air from the atmosphere and after compressing and heating it, a process that occurs in all heat engines, the energy and momentum given to the air forces it out of the propelling nozzle at a velocity of up to 2,000 feet per second or about 1,400 miles per hour. On its way through the engine, the air gives up some of its energy and momentum to drive the turbine that powers the compressor.

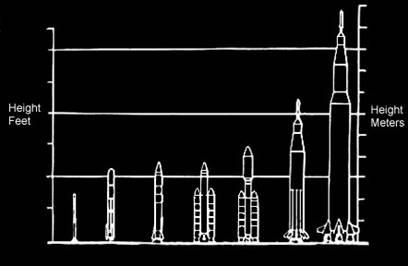

The mechanical arrangement of the gas turbine engine is simple, for it consists of only two main rotating parts, a compressor (Part 3) and a turbine (Part 5), and one or a number of combustion chambers (Part 4). The mechanical arrangement of various gas turbine engines is shown in fig. 1-9. This simplicity, however, does not apply to all aspects of the engine, for as described in subsequent Parts the thermo and aerodynamic problems are somewhat complex. They result from the high operating temperatures of the combustion chamber and turbine, the effects of varying flows across the compressor and turbine blades, and the design of the exhaust system through which the gases are ejected to form the propulsive jet.

At aircraft speeds below approximately 450 miles per hour, the pure Jet engine is less efficient than a propeller-type engine, since its propulsive efficiency depends largely on its forward speed; the pure turbo-jet engine is, therefore, most suitable for high forward speeds. The propeller efficiency does, however, decrease rapidly above 350 miles per hour due to the disturbance of the airflow caused by the high blade-tip speeds of the propeller. These

characteristics have led to some departure from the use of pure turbo-jet propulsion where aircraft operate at medium speeds by the introduction of a combination of propeller and gas turbine engine.

The advantages of the propeller/turbine combination have to some extent been offset by the introduction of the by-pass, ducted fan and prop fan engines. These engines deal with larger comparative airflows and lower jet velocities than the pure jet engine, thus giving a propulsive efficiency, which is comparable to that of the turbo-prop and exceeds that of the pure jet engine (fig. 1-10).

The turbo/ram jet engine (fig. 1-11) combines

the turbo-jet engine (which is used for speeds up to Mach 3) with the ram jet engine, which has good performance at high Mach numbers.

A duct that has a variable intake at the front and an afterburning jet pipe with a variable nozzle at the rear surrounds the engine. During take-off and acceleration, the engine functions as a conventional turbo-jet with the afterburner lit, at other flight conditions up to Mach 3, the afterburner is inoperative. As the aircraft accelerates through Mach 3, the turbo-jet is shut down and the intake air is diverted from the compressor, by guide vanes, and ducted straight into the afterburning jet pipe, which becomes a ram jet combustion chamber. This engine is suitable for an aircraft requiring high speed and sustained high Mach number cruise conditions where the engine operates in the ram jet mode.

The turbo-rocket engine (fig. 1-12) could be considered as an alternative engine to the turbo/ram jet however it has one major difference in that it carries its own oxygen to provide combustion

The engine has a low pressure compressor driven by a multi-stage turbine the power to drive the turbine IS derived from combustion of kerosene and liquid oxygen in a rocket-type combustion chamber Since the gas temperature will be in the order of 3.500 deg. C. additional fuel is sprayed into the combustion chamber for cooling purposes before the gas enters the turbine. This fuel-rich mixture (gas) is then diluted with air from the compressor and the surplus fuel burnt in a conventional afterburning system.

Although the engine is smaller and lighter than the turbo/ram jet, it has a higher fuel consumption This tends to make it more suitable for an interceptor or space-Iauncher type of aircraft that requires high speed, high altitude performance and normally has a flight plan that is entirely accelerative and of short duration

Compressor:

Both types are driven by the engine turbine and are usually coupled direct to the turbine shaft.

The centrifugal flow compressor (fig. 3-1) is a single or two-stage unit employing an impeller to accelerate the air and a diffuser to produce the required pressure rise. The axial flow compressor (fig. 3- 7 and fig. 3-8) is a multi-stage unit employing alternate rows of rotating (rotor) blades and stationary (stator) vanes, to accelerate and diffuse the air until the required pressure rise is obtained. In some cases, particularly on small engines, an axial compressor is used to boost the inlet pressure to the centrifugal.

With regard to the advantages and disadvantages of the two types, the centrifugal compressor is usually more robust than the axial compressor and is also easier to develop and manufacture. The axial compressor however consumes far more air than a centrifugal compressor of the same frontal area and can be designed to attain much higher pressure ratios. Since the airflow is an important factor in determining the amount of thrust, this means the axial compressor engine will also give more thrust for the same frontal area. This, plus the ability to increase the pressure ratio by addition of extra stages, has led to the adoption of axial compressors in most engine designs. However, the centrifugal compressor is still favoured for smaller engines where its simplicity and ruggedness outweigh any other disadvantages.

Leads to improved specific fuel consumption for a given thrust.

The trend to high pressure ratios which has favoured the adoption of axial compressors is because of the improved efficiency that results, which in turn

THE CENTRIFUGAL FLOW COMPRESSOR

Centrifugal flow compressors have a single or double-sided impeller and occasionally a two-stage, single sided impeller is used, as on the Rolls-Royce Dart. The impeller is supported in a casing that also contains a ring of diffuser vanes. If a double-entry impeller is used, the airflow to the rear side is reversed in direction and a plenum chamber is required

Principles of operation

The Impeller is rotated at high speed by the turbine and air is continuously induced into the centre of the impeller Centrifugal action causes it to flow radially outwards along the vanes to the impeller tlp thus accelerating the air and also causing a rise In pressure to occur The engine intake duct may contain vanes that provide an initial swirl to the air entering the compressor.

The air on leaving the Impeller passes into the diffuser section where the passages form divergent nozzles that convert most of the kinetic energy into pressure. In practice

It is usual to design the compressor so that about half of the pressure rise occurs in the impeller and half in the diffuser.

To maximize the airflow and pressure rise through the compressor requires the impeller to be rotated at high speed therefore Impellers are designed to operate at tip speeds of up to 1 600 ft per sec. By operating at such high tip speeds the air velocity from the impeller is increased so that greater energy is available for conversion to pressure.

To maintain the efficiency of the compressor, it is necessary to prevent excessive air leakage between the impeller and the casing this is achieved by keeping their clearances as small as possible.

Construction

The construction of the compressor centres around the impeller, diffuser and air Intake system The impeller shaft rotates In ball and roller bearings and is either common to the turbine shaft or split in the centre and connected by a coupling, which is usually designed for each of detachment.

Impellers

The impeller consists of a forged disc with integral, radially disposed vanes on one or both sides (fig 3-5) forming convergent passages in conjunction with the compressor casing The vanes may be swept back. But for ease of manufacture straight radial vanes are usually employed. To ease the air from axial flow in the entry duct on to the rotating impeller, the vanes in the centre of the impeller are curved in the direction of rotation. The curved sections may be integral with the radial vanes or formed separately for easier and more accurate manufacture.

Diffusers

The diffuser assembly may be an integral part of the compressor casing or a separately attached assembly. In each instance it consists of a number of vanes formed tangential to the impeller. The vane passages are divergent to convert the kinetic energy into pressure energy and the inner edges of the vanes are in line with the direction of the resultant airflow from the impeller. The clearance between the impeller and the diffuser is an important factor, as too small a clearance will set up aerodynamic buffeting impulses that could be transferred to the impeller and create an unsteady airflow and vibration.

THE AXIAL FLOW COMPRESSOR

An axial flow compressor (fig. 3-7 and fig. 3-8) consists of one or more rotor assemblies that carry blades of airfoil section. These assemblies are mounted between bearings in the casings, which incorporate the stator vanes. The compressor is a multi-stage unit as the amount of pressure increase by each stage is small; a stage consists of a row of rotating blades followed by a row of stator vanes. Where several stages of compression operate in series on one shaft it becomes necessary to vary the stator vane angle to enable the compressor to operate effectively at speeds below the design condition. As the pressure ratio is increased the incorporation of variable stator vanes ensures that the airflow is directed onto the succeeding stage of rotor blades at an acceptable angle.

From the front to the rear of the compressor, i.e. from the low to the high pressure end, there is a gradual reduction of the air annulus area between the rotor shaft and the stator casing. This is necessary to maintain a near constant air axial velocity as the density increases through the length of the compressor. The convergence of the air annulus is achieved by the tapering of the casing or rotor. A combination of both is also possible, with the arrangement being influenced by manufacturing problems and other mechanical design factors.

A single-spool consists of one rotor assembly and stators with as many stages as necessary to achieve the desired pressure ratio and all the airflow from the intake passes through the compressor. The multi-spool compressor consists of two or more rotor assemblies each driven by their own turbine at an optimum speed to achieve higher pressure ratios and to give greater operating flexibility.

Although a twin-spool compressor can be used for a pure jet engine, it is most suitable for the by-pass type of engine where the front or low-pressure compressor is designed to handle a larger airflow than the high-pressure compressor. Only a percentage of the air from the low-pressure compressor passes into the high-pressure compressor; the remainder of the air, the by-pass flow, is ducted around the high-pressure compressor. Both flows mix in the exhaust system before passing to the propelling nozzle. This arrangement matches the velocity of the jet nearer to the optimum requirements of the aircraft and results in higher propulsive efficiency, hence lower fuel consumption. For this reason the pure jet engine where all the airflow passes through the full compression cycle is now obsolete for all but the highest speed aircraft.

With the high by-pass ratio turbo-fan this trend is taken a stage further. The intake air undergoes only one stage of compression in the fan before being split between the core or gas generator system and the by-pass duct in the ratio of approximately one to five. This results in the optimum arrangement for passenger and/or transport aircraft flying at just below the speed of sound. The fan may be coupled to the front of a number of core compression stages (two shaft engine) or a separate shaft driven by its own turbine (three shaft engine).

INTRODUCTION

The combustion chamber has the difficult task of burning large quantities of fuel. supplied through the fuel spray nozzles. With extensive volumes of air supplied by the compressor and releasing the heat in such a manner that the air IS expanded and accelerated to give a smooth stream of uniformly heated gas at all conditions required by the turbine. This task must be accomplished with the minimum loss in pressure and with the maximum heat release for the limited space available.

The amount of fuel added to the air will depend upon the temperature rise required. However. the maximum temperature is limited to within the range of 850 to 1700 deg. C. by the materials from which the turbine blades and nozzles are made The air ha already been heated to between 200 and 550 deg. C by the work done during compression, giving temperature rise requirement of 650 to 1150 deg. C from the combustion process. Since the gas temperature required at the turbine varies with engine thrust. and in the case of the turbo-propeller engine upon the power required. The combustion chamber must also be capable of maintaining stable an efficient combustion over a wide range of engine operating conditions.

Efficient combustion has become increasingly important because of the rapid rise in commercial aircraft traffic and the consequent increase atmospheric pollution that is seen by the general public as exhaust smoke

Air from the engine compressor enters the combustion chamber at a velocity up to 500 feet per second, but because at this velocity the air speed is far too high for combustion, the first thing that the chamber must do is to diffuse it, i.e. decelerate it and raise its static pressure. Since the speed of burning kerosene at normal mixture ratios is only a few feet per second, any fuel lit even in the diffused air stream, which now has a velocity of about 80 feet per second, would be blown away. A region of low axial velocity has therefore to be created in the chamber, so that the flame will remain alight throughout the range of engine operating conditions.

In normal operation, the overall air/fuel ratio of a combustion chamber can vary between 45.1 and 130.1. However, kerosene will only burn efficiently at, or close to, a ratio of 15.1, so the fuel must be burned with only part of the air entering the chamber, in what is called a primary combustion zone. This is achieved by means of a flame tube (combustion liner) that has various devices for metering the airflow distribution along the chamber

The snout or entry section takes in approximately 20 per cent of the air mass flow. Immediately downstream of the snout are swirl vanes and a perforated flare, through which air passes into the primary combustion zone. The swirling air induces a flow upstream of the centre of the flame tube and promotes the desired recirculation. The air not picked up by the snout flows into the annular space between the flame tube and the air casing.

Through the wall of the flame tube body, adjacent to the combustion zone, are a selected number of secondary holes through which a further 20 per cent of the main flow of air passes into the primary zone. The air from the swirl vanes and that from the secondary air holes interacts and creates a region of low velocity recirculation. This takes the form of a toroidal vortex, similar to a smoke ring, which has the effect of stabilizing and anchoring the flame (fig. 4-3). The recirculating gases hasten the burning of freshly injected fuel droplets by rapidly bringing them to ignition temperature.

It is arranged that the conical fuel spray from the nozzle intersect the recirculation vortex at its centre. This action, together with the general turbulence in the primary zone, greatly assists in breaking up the fuel and mixing it with the incoming air.

The temperature of the gases released by combustion is about 1,800 to 2,000 deg. C., which is far too hot for entry to the nozzle guide vanes of the turbine. The air not used for combustion, which amounts to about 60 per cent of the total airflow, is therefore introduced progressively into the flame tube. Approximately a third of this is used to lower the gas temperature in the dilution zone before it enters the turbine and the remainder is used for cooling the walls of the flame tube. This is achieved by a film of cooling air flowing along the inside surface of the flame tube wall, insulating it from the hot combustion gases (fig. 4-4). A recent development allows cooling air to enter a network of passages within the flame tube wall before exiting to form an insulating film of air, this can reduce the required wall cooling airflow by up to 50 per cent. Combustion should be completed before the dilution air enters the flame tube, otherwise the incoming air will cool the flame and incomplete combustion will result.

An electric spark from an igniter plug initiates combustion and the flame is then self-sustained.

The design of a combustion chamber and the method of adding the fuel may vary considerable, but the airflow distribution used to effect and maintain combustion is always very similar to that described.

INTRODUCTION

The turbine has the task of providing the power to drive the compressor and accessories and, in the case of engines which do not make use solely of a jet for propulsion, of providing shaft power for a propeller or rotor It does this by extracting energy from the hot gases released from the combustion system and expanding them to a lower pressure and temperature. High stresses are involved in this process, and for efficient operation the turbine blade tips may rotate at speeds over 1,500 feet per second The continuous flow of gas to which the turbine is exposed may have an entry temperature between 850 and 1,700 deg. C and may reach a velocity of over 2,500 feet per second in parts of the turbine

To produce the driving torque the turbine may consist of several stages each employing one row of stationary nozzle guide vanes and one row of moving blades. The number of stages depends upon the relationship between the power required from the fan engines that feature an intermediate pressure system another turbine may be interposed between the high and low pressure turbines, thus forming a triple-spool system. On some engines, driving torque is derived from a free-power turbine. This method allows the turbine to run at its optimum speed because it is mechanically independent of other turbine and compressor shafts.

The number of shafts, and therefore turbines varies with the type of engine. High compression ratio engines usually have two shafts, driving high and low pressure compressors. The mean blade speed of a turbine has considerable effect on the maximum efficiency possible for a given stage output For a given output the gas velocities, deflections, and hence losses are reduced in proportion to the square of higher mean blade speeds Stress in the turbine disc increases as the square of the speed therefore to maintain the same stress level at higher speed the sectional thickness, hence the weight, must be increased disproportionately. For this reasons the final design is a compromise between efficiency and weight. Engines operating at higher turbine inlet temperatures are thermally more efficient and have an improved power to weight ratio By-pass engines have abetter propulsive efficiency and thus can have a smaller turbine for a given thrust.

The design of the nozzle guide vane and turbine blade passages is based broadly on aerodynamic considerations, and to obtain optimum efficiency, compatible with compressor and combustion design, the nozzle guide vanes and turbine blades are of a basic aerofoil shape. There are three types of turbine, impulse, reaction and a combination of the two known as impulse-reaction. In the impulse type the total pressure drop across each stage occurs in the fixed nozzle guide vanes, which, because of their convergent shape, increase the gas velocity whilst reducing the pressure. The gas is directed onto the turbine blades which experience an impulse force caused by the impact of the gas on the blades In the reaction type the fixed nozzle guide vanes are designed to alter the gas flow direction without changing the pressure. The converging blade passages experience a reaction force resulting from the expansion and acceleration of the gas. Normally gas turbine engines do not use pure impulse or pure

reaction turbine blades but the impulse-reaction combination (fig 5-5). The proportion of each principle incorporated in the design of a turbine is largely dependent on the type of engine in which the turbine is to operate, but in general it is about 50 per cent impulse and 50 per cent reaction. Impulse-type turbines are used for cartridge and air starters.

Rockets:

Function: A solid propellant is a monopropellant fuel-a single mixture of several chemicals (the oxidizing agent and the reducing agent or fuel). This fuel, as implied, is in its solid state and has a preformed or moulded shape. The propellant grain, this interior shape of the core is an important factor in determining a rocket's performance. The variables determining grain-relative performance are core surface area and specific impulse.

Surface area is the amount of propellant exposed to interior combustion flames, existing in a direct relationship with thrust. An increase in surface area will increase thrust but will reduce burn-time since the propellant is being consumed at an accelerated rate. The optimal thrust is typically a constant one, which can be achieved by maintaining a constant surface area throughout the burn. Examples of constant surface area grain designs include: end burning, internal-core and outer-core burning, and internal star core burning (figure 3). Various shapes are used for the optimisation of grain-thrust relationships since some rockets may require an initially high thrust component for takeoff while a lower thrust will suffice its post-launch regressive thrust requirements. Such a compromise has implications as seen, but it optimises overall rocket performance. Complicated grain core patterns, in controlling the exposed surface area of the rocket's fuel, often have parts coated with a non-flammable plastic (such as cellulose acetate). This coat prevents internal combustion flames from igniting that portion of fuel, ignited only later when the burn reaches the fuel directly.

Specific Impulse, the thrust per unit propellant burned each second, measures rocket performance and more specifically, internal thrust production a product of pressure and heat. Thrust in chemical rockets (inclusive of both solid and liquid fuelled rockets, is a product of the hot and expanding gasses created in the combustion of an explosive fuel (a reduction-oxidation reaction). The degree of the fuel's explosive power coupled with the rate of combustion is the specific impulse. In designing the rocket's propellant grain specific impulse must be taken into account since it can be the difference betwixt a conflagration of failure (explosion), and a successfully optimised thrust-producing rocket. If a propellant with a high specific impulse is used as the fuel for a rocket whose grain design offers a high surface area ratio, high amounts of thrust will ensue ignition. And if the engine grain casing cannot withstand the extreme pressure and temperature it will rupture and explode. Thus, the function involving the variables of both specific impulse and surface area must be considered in grain design.

The departure from the use of gunpowder to more powerful fuels (higher specific impulses) marks the development of modern solid fuelled rockets. Once the chemistry behind rocket fuels (fuels provide their own 'air' to burn) was discovered, scientists sought the evermore-powerful fuel, constantly approaching new limits. A composite propellant is a mechanically mixed combination of the oxidizer and the fuel. Some common solid oxidizers are: ammonium per chlorate (NH4-ClO4) and ammonium nitrate (NH4-KNO3), chemicals providing far more oxygen than potassium nitrate (KNO3), the oxidizing agent in gunpowder. These oxidizers are often mixed, in making composite propellants, with synthetic rubbers such as: polystyrenes, polysulfides, and polyurethane's. Another type of propellant is homogeneous where the oxidizer and the fuel are combined as one molecule. Propellants of this type often use a double base (combination of two propellants) of nitrocellulose and nitro-glycerine (C3H5 (ONO2) 3).

Advantages/Disadvantages: Solid fuelled rockets are relatively simple

rockets. This is their chief advantage, but it also has its

drawbacks. Once a solid rocket is ignited it will consume the entirety of

its fuel, without any option for shutoff or thrust adjustment. Another

key disadvantage is the danger involved in the premixed fuels of monopropellant

rockets. In the double-base homogeneous nitrocellulose-nitro-glycerine

propellant, for example the nitro-glycerine is too unstable (sufficient shock

will detonate) to use individually add thus a more stable propellant like

nitrocellulose (a form of gunpowder) is added. Composite engines, having

the fuel and oxidizer as separately mixed elements, are less sensitive to shock

and therefore safer to use. A relatively low specific impulse limits the

use of solid rockets when large amounts of thrust precondition. The

Saturn V moon rocket used nearly 8 million pounds of thrust that would not have

been feasible with the use of solid propellant, requiring a high specific

impulse liquid propellant. The ease of storage of solid propellant

rockets is another main advantage employing a high level use in the

military. Some of these rockets are small missiles such as Honest John

and Nike Hercules; others are large ballistic missiles such as Polaris,

Sergeant, and Vanguard. Liquid propellants may offer better performance,

but the difficulties in propellant storage and handling of liquids near

absolute zero (0 degrees Kelvin) has limited their use unable to meet the

stringent demands the military requires of its firepower.

Function: As with conventional solid fuels rockets, liquid fuelled rockets burn a fuel and an oxidizer. The apparent distinction is the liquid state of the fuel and the oxidizer. Several layers of complexity are added to this rather innocent looking point. The unfolding performed here will illuminate the necessity for this complexity.

There are two metal tanks holding the fuel and oxidizer respectively. Due to properties (discussed later) of these two liquids, they are typically loaded into their tanks just prior to launch. The separate tanks are necessary, for many liquid fuels burn upon contact. Upon a set launching sequence two valves (see figure 4.2) open, allowing the liquid, hitherto blocked, to flow down the pipe-work. If these valves simply opened allowing the liquid propellants to flow into the combustion chamber at their own leisure, a weak (if any at all) thrust production would incur as well as an unstable flow rate (leading to a unstable thrust rate). Two solutions have been devised to solve this problem: (1) a pressurized gas feed and (2) a turbo pump feed.

The simpler of the two, the pressurized gas feed, adds a tank of high-pressure gas to the propulsion system (see figure 4.1). The gas, an unreactive, inert, and light gas (such as helium), is held and regulated, under intense pressure, by a valve/regulator as seen in figure 4.2. The purpose of this gas is maintaining a pressure forced flow of the liquid propellants, pushing them out, as one might expend liquids from a straw by blowing into it. As noted, more than a valve is needed to execute this operation in a rocket, thus the regulator controls the amount of gas flowing into each propellant tank. If only a valve, opened during the initial launch sequence, controlled the gas the gas would flow to form equilibrium of pressures in the gas tank, the piping, and the propellant tanks. This is problem. Although the gas tank will be able to withstand the equilibrium pressure, the piping and the propellant tanks might not and the rupture ensuing will cause a conflagration of failure. One could use propellant tank able to bear such pressures but the mass of these tanks would be exorbitant. Thus, the regulator controls a flow that maintains a constant pressure within the propellant tanks--a situation solving the problem of fuel transfer. The constant force (pressure) exerted on the surface of the propellants will give a constantly regulated flow as they are pushed into the combustion chamber (see figure 3.6). The regulator functions to maintain these constant flows by adjusting the flow of the gas entering the propellant tanks. The gas flow must constantly be regulated; as pressure is fed into the propellant tanks, to compensate for the fuel leaving, pressure is removed from the gas storage tank. And this gas is progressively being sent into the propellant tanks, as more of this low-pressure gas is necessary to maintain a constant pressure within the propellant tanks. The pressure of a gas is indirectly related to the volume the gas occupies. This law explains how the pressure decreases in the gas supply tank (whose volume does not change), and how this action can maintain a constant pressure inside the propellant tanks (whose volumes increase, as the liquid propellants exit, with the influx the gas in effect replacing the fuel). Given these criteria the flow of propellants is ultimately controlled by the pressure the system is set to maintain. Thus, a high rate of propellant flow is achieved by simply increasing the set pressure of the system.

The second, and often preferred, solution to the fuel transfer problem is a turbo pump. Figure 5 shows this type of propulsion design. A turbo pump is the same as regular pump in function and bypasses a gas-pressurized system by sucking out the propellants and accelerating them into the combustion chamber. The idea seems simple but the implementation of it not. The gas-pressurized method worked because great pressures could be easily stored in the gas storage tank, but in the turbo pump model the pump has to do all the work. And energy to run the turbo pump must be generated. The large propellant tanks looming over the turbo pump suggest a source of stored energy. To convert this chemically stored energy to productive pump energy a miniature rocket engine is added (yes, one is not enough). This small engine typically uses the same propellants as the main rocket but at a much lower thrust production due to decreased size. The exhaust (or thrust) of this engine beats down upon a turbine (a propeller-like disk with hundreds of blades), causing it to spin rapidly. This action converts the chemical energy into the mechanical energy the turbo pump needs to operate. A shaft (figure 5.5), connected to the rotating turbine, spreads in opposite directions to two additional turbines. The rotation of these turbines, controlled by a gear train (a set of gears) along the shaft, controls the flow of the propellants the spinning of the turbines induces. This configuration is analogous to a high power waterwheel accelerating the water in a stream, where the stream in the turbo pump model is the piping that leads to the combustion chamber. Note that the three turbines in this model are enclosed and entirely isolated from one another connected only by the shaft. Also note that the blades on the on the outer two turbines (the propellant accelerating turbines) are both powered, via the same shaft, by the interior, rocket powered turbine.

Now that the propellants are being gushed into the combustion chamber we run into more complications. As the oxidizer and fuel are mixed and ignited inside the combustion chamber thrust is created. Ultimately this thrust will push the rocket upwards but while inside the thrust wants to push everywhere, even into the piping the propellant is coming out of. The intense pressure created in this converging section of the propulsion system must be accounted for in determining rate of propellant flow and combustion chamber shear strength. If the rate of propellant flow is to small the propellant will not be bale to enter the combustion chamber--a problem avoided by the proper use of a gas-pressurized or turbo pump system. If the combustion chambers integrity cannot maintain burn-time pressures the engine will explode, thus high-strength (although heavy) steel or an alloyed metal (composed of several metals; lighter) or composite material is used. Another problem is the intense heat created by combustion of the fuel and oxidizer. Circulating the propellants around the exterior of the combustion chamber and nozzle usually solves this. The propellants are (as will be seen in the following paragraph) extremely cold and they evaporate slightly, as the flow over the hot surface of the combustion chamber, absorbing some of the engine's heat. This evaporation actually has three effects: (1) as mentioned, evaporative cooling, (2) increase in propellant flow (from increase in total pressure of increased volume evaporated gas), and (3) catalytic (although temperature of the relatively adiabatic system might increase, the creation of more gaseous reactants (which burn more efficiently) will probably improve overall performance).

Liquid Oxygen is the most common oxidizer used. Other oxidizers used in liquid propellant rockets including: hydrogen peroxide (95%, H2O2), nitric acid (HNO3), and liquid fluorine. Of these choices liquid fluorine, given a control fuel, produces the highest specific impulse (amount of thrust per unit propellant). But due to difficulties in handling this corrosive element, and due to the high temperatures it burns at, liquid fluorine is rarely used in modern liquid fuelled rockets. At STP (standard temperature, 25 degrees Celsius, and pressure, 1 ATM or 760 torr) oxygen and fluorine are gaseous elements. This state could be used, and combustion would occur, but the amount of gaseous oxygen or fluorine, storable in the oxidizer tank, would be insufficient in producing useful thrust. Thus, the temperatures of these gases are significantly reduced, thereby changing into a liquid state. And it is in this form that the oxidizers must be used. The reason for this is simply that the atoms of oxygen or fluorine are much closer to one another in the liquid state-the oxidizer is more concentrated and thus more useful. The liquid fuels often used include: liquid hydrogen, liquid ammonia (NH3), hydrazine (N2H4), and kerosene (hydrocarbon).

Advantages/Disadvantages:

Liquid propellant rockets are the most powerful (in terms gross thrust)

propulsion systems available. They are also among the most variable, that

is to say, adjustable given a large array of valves and regulators to control

and augment rocket performance. Unfortunately the last point makes liquid

propellant rockets intricate and complex. Not that this scares away the

designers (they are 'rocket scientists') but what it does do is lower

reliability. Figures 4 and 5 may look relatively simple, but you may have

noted that many parts and pipes and wires that connect everything were

omitted. A real modern liquid bipropellant engine has thousands of piping

connections carrying various cooling, fuelling, or lubricating fluids.

Also the various sub-parts such as the turbo pump or regulator consist of a

separate vertigo of pipes, wires, control valves, temperature gauges and

support struts. Given this myriad of parts, the chance of one integral

function failing is large. Thus, many rockets are rated in terms of

reliability--one of the reasons for the Titan series' popularity. As

noted before the liquid oxygen is the most commonly used oxidizer, but it too

has its drawbacks. To achieve the liquid state of this element, a

temperature of -183 degrees Celsius must be obtained--conditions under which

oxygen readily evaporates, losing a large sum of oxidizer just while

loading.  Nitric acid, another

powerful oxidizer, contains 76% oxygen, is in its liquid state at STP, and has

a high specific gravity--all great advantages. The latter point is a

measurement similar to density and as it rises higher so to does the

propellant's performance. But, nitric acid is hazardous in handling

(mixture with water produces a strong acid) and produces harmful by-products in

combustion with a fuel, thus its use is limited.

Nitric acid, another

powerful oxidizer, contains 76% oxygen, is in its liquid state at STP, and has

a high specific gravity--all great advantages. The latter point is a

measurement similar to density and as it rises higher so to does the

propellant's performance. But, nitric acid is hazardous in handling

(mixture with water produces a strong acid) and produces harmful by-products in

combustion with a fuel, thus its use is limited.

Piston Engines:

Technical Overview

Before we examine the tariff provisions involved and get into the inner workings of the tariff classification process, a brief primer on engine technology would be helpful.

Most sources commonly define an engine as a machine or apparatus for converting energy into mechanical power or motion. The engine's purpose is to translate the potential energy locked in a fuel into a rotating force called 'torque', which is a twisting force or action that performs work. It is created in the engine by burning a mixture of fuel and air at a controlled rate. This is called combustion and when it occurs within the confines of an enclosed cylinder, it is referred to as internal combustion, as opposed to engines, which burn their fuel externally like the steam engine of an old-fashioned paddle wheeler that employs steam raised in a fire-driven boiler to drive a piston up and down in a cylinder.

Internal combustion engines, then, for the purposes of this discussion, are those in which power is produced by burning fuel inside a combustion chamber or cylinder containing a piston which goes up and down in a reciprocating motion resulting from the combustion. Extending down from the piston is a connecting rod, which links the piston to the crankshaft. The connecting rod and crankshaft convert the reciprocating motion of the piston into motion or work.

Technically, internal combustion engines can be categorized in many ways. The most common ways of talking about engines include the combustion cycle, the valve location, the cooling system, the number and placement of the cylinders and the type of fuel used.

Most internal combustion

engines use a two- or four-stroke combustion cycle. The vast majority of

automobile engines are of the four-stroke cycle type. In this type, there is an

intake stroke, wherein the intake valve opens to admit the air/fuel mixture to

be burned during one complete cycle. Next is the compression stroke, wherein

the mixture is squeezed into a smaller volume than as admitted. The power

stroke, which comes next, ignites the mixture, which forcefully thrusts the

piston into turning the crankshaft, whose power is then transmitted into motion

or work. Finally, the exhaust stroke results in the opening of the exhaust

valve to vent the spent gases of the power stroke. The rotary engine, or Wankel

engine (named after its inventor), also uses a four-stroke cycle, but does not

employ conventional pistons. Instead it uses triangular rotors which function

like pistons, but in place of the up and down reciprocating motion of the

piston, the rotors continually revolve in the same direction as their eccentric

shafts.

Most internal combustion

engines use a two- or four-stroke combustion cycle. The vast majority of

automobile engines are of the four-stroke cycle type. In this type, there is an

intake stroke, wherein the intake valve opens to admit the air/fuel mixture to

be burned during one complete cycle. Next is the compression stroke, wherein

the mixture is squeezed into a smaller volume than as admitted. The power

stroke, which comes next, ignites the mixture, which forcefully thrusts the

piston into turning the crankshaft, whose power is then transmitted into motion

or work. Finally, the exhaust stroke results in the opening of the exhaust

valve to vent the spent gases of the power stroke. The rotary engine, or Wankel

engine (named after its inventor), also uses a four-stroke cycle, but does not

employ conventional pistons. Instead it uses triangular rotors which function

like pistons, but in place of the up and down reciprocating motion of the

piston, the rotors continually revolve in the same direction as their eccentric

shafts.

The two-stroke cycle engine reduces these strokes from four to two and does not employ valves. Two-stroke engines can operate at very high speeds and can be compact and light. Thus, they are popular in small engine operations such as chain saws, lawn mowers, marine outboard motors and the like. They are not noted for fuel efficiency or emissions control.

Haupt | Fügen Sie Referat | Kontakt | Impressum | Nutzungsbedingungen